bubble insulation

Aluminum Foil Bubble Insulation,Double Bubble Thermal Insulation,Roof Building Construction Material

Product Introduction:

The product consists of two layers of aluminum foil with plastic bubble laminated between the aluminum foil,provides excellent insulation: Reflects up to 97% of radiant energy in addition to resisting other types of heat transfer from conduction, convection and radiation. The two side aluminum foil forms an effective barrier against moisture, air currents and vapors.

It is an economical solution for a wide range of industrial, manufacturing and consumer applications.

Application:

Roof,Ceiling,Wall,Floor,Attic,Livestock Shelters,Basement,Factory buildings,Duct wrappings,Container liner,Sun-stop cover and vehicles.

1. Thermal insulation and light inflecting in the constrction and protection for both cold winter and water piper

2. Separation of refrigerator,warm keeping for center air-conditioned,refrigerator and other home appliances

3. Thermal insulation,sound absorption and noise reduction for car ,train, refrigerator car and laboratory, moisture proof cushion for traveling.

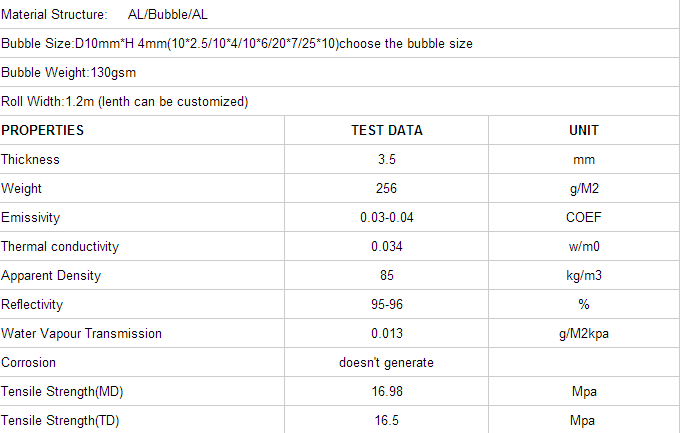

Data Sheet:

Installation methods and Installation Projects:

- Measure the metal roof to determine the amount of bubble foil wrap insulation required for the project. Purchase approximately 10 to 15 percent more product than required to account for overlapping and to provide the proper air gap between the purlins -- the horizontal lengths of wood that support the roof panels between the rafters.

- Cover the metal roof purlins with double-sided adhesive tape. Unroll the foil wrap insulation and attach it to the first purlin. Continue to unroll the foil insulation and attach it the remaining purlins, paying attention to allow the insulation to sag at least 1 inch between the horizontal members. The sagging provides an air gap that raises the insulation’s efficiency.

- Continue to attach the Aluminum foil bubble insulation to the metal roofing purloins, overlapping the adjoining sheets 2 inches as you go. This is a temporary hold to keep the bubble foil wrap in place while you prepare the next step.

- Secure the bubble foil to the framing members with furring strips. Attach the furring strips perpendicular to the purloins every 24 inches to the framing members with 2-inch metal screws, paying attention to not disrupt the insulation’s sagging. Use a drill equipped with a screwdriver bit to drive the screws into the framing members.

- Cover the seams of the bubble insulation with foil tape.

Packaging and Loading: